- Selamat datang di website PT Fiqry Jaya Manunggal. Semoga anda senantiasa sehat afiat. Kami siap melayani anda

Reliability Centered Maintenance (RCM), Fundamental for Maintenance Energy

Rp 7.950.000| Stok | Tersedia |

| Kategori | Maintenance, Training |

Trainer: Ir. Ahmad Taufik Joenoes, M.Eng., Ph.D., CMRP.

16-23 October, 2024, Sorowako, Sulawesi

Reliability Centered Maintenance (RCM), Fundamental for Maintenance Energy

BACKGROUND:

Reliability Centered Maintenance (RCM) is an essential strategy for optimizing maintenance programs, particularly in industries such as energy, manufacturing, and petrochemicals. By implementing RCM, companies can prevent costly equipment failures through predictive and preventive maintenance techniques. This RCM training for Maintenance Energy 2024 will provide participants with the necessary knowledge to apply effective maintenance strategies and reduce operational costs, ensuring smooth production processes and asset reliability.

Teams implementing RCM use maintenance planning, asset condition monitoring, predictive maintenance and preventive maintenance to avoid costly equipment failure.

This Reliability Centered Maintenance (RCM) course is beneficial especially for continuous process industry and utilizes sophisticate and expensive production equipment, such as: Mining Industry, Electricity Plant, Petrochemical Plant, Marine Industry, Manufacturing, Automotive, Assembling Industry, Aviation, Construction, Pulp and Paper, Oil and Gas, etc. The course is designed by considering the need of maintenance method that reliable to ensure the success of production, a method of maintenance to push downs a break down or unplanned disturbance. The requirement of efficient and effective method of maintenance becomes more important when plant facility is automatic system. The big loss can come, if it is late to improve maintenance operation system, low productivity, wasting working hours, last production, engine big failure, and in-harmony relation with customer, successful.

Further consulting & implementation is suggested to ensure real added values benefits the company.

OBJECTIVES:

After this training, participants will be able to:

- To understand the Reliability Centered Maintenance (RCM) as basic of maintenance management implementation or as an aid-tool for cost

- management and as part of project management.

- To understand maintenance philosophy based an the third generation of previous maintenance generation i.e.: first generation (breakdown maintenance) and second generation (preventive maintenance)

- To avoid total failure by knowing what kind of failure will happen.

- To understand root cause mechanism of failure

- To minimize maintenance cost and operate the equipment until maximum capacity

TARGETTED PARTICIPANTS:

The following selected participants should attend this course:

- Maintenance Engineer/ Superintendent/ Supervisor

- Rotating Engineer/ Superintendent/ Supervisor

- Power Plant Engineer/ Superintendent /Supervisor

- Manufacturing Manager

- Everybody who wants to broaden knowledge and interest in this topics

TRAINING CONTENT:

Theory Basic Maintenance

- Definition of Maintenance

- Various Type of Maintenances (PM, PdM, TQM, RCM, CBM)

- Reliability, Maintainability and Availability.

- Key Performance Indicator (KPI) for Maintenance

- Overall Equipment Effectiveness (OEE) Determination

Functional Failure Analysis (FFA)

- Operational Context

- Functional Failure (Failed States)

- Root Cause Failure Analysis – Turbine, Pumps, Motor, Generator and Others.

Critical Item Selection

- Risk (Criticality) Matrix

- Likelihood of Failure Formulation and Scoring

- Consequence of Failure Formulation and Scoring

- Criticality Categorization

Data Collection and Analysis

- Potential Failure (P-F) Curve

- Infrared Thermal Imaging

- Vibration Analysis

- Lubrication Analysis

- Electrical Testing & Monitoring

- Data Trend Analysis

Failure Mode and Effect and Criticality Analysis

- Failure Modes for Various Equipment Type

- Failure Causes (Damage Mechanism) and Effect Determination

- Failure Rate of Credible Failure Modes

- Detectability (Inspect-ability)

- Risk Priority Number (RPN) Determination

Maintenance Actions

- Decision Logic Path

- Inspection, Test and Maintenance Plan (Task List)

- Task Grouping, Job Bundling, Levelling and Work Order

- Critical Spare Parts Identification & Inventory Management

Maintenance Intervals

- Mean Time Between Failure (MTBF)

- Mean Time Between Repair (MTTR)

- Remaining Life Assessment

- Inspection, Test & Repair Time Interval for Static Equipment, Rotating Electrical Equipment and Instrument.

Preventive Maintenance Comparation Analysis

- Vendor’s Recommendation Vs Condition Based Maintenance

- Risk Based Maintenance Scheduling

Road Map toward RCM Implementation & Roll-out

Reliability Centered Maintenance (RCM), Fundamental for Maintenance Energy

HVAC Operation, Maintenance, & Troubleshooting

BACKGROUND: HVAC systems play a crucial role in maintaining optimal indoor comfort by regulating heating, ventilation, and air conditioning. A key component of these systems is the hydronic system, which uses water or other liquids for efficient heat transfer. Understanding the operation, maintenance, and troubleshooting of HVAC systems, including hydronic and refrigeration components, is essential…

Rp 7.950.000

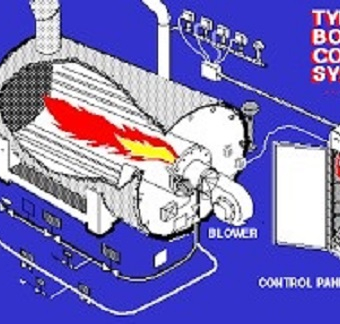

Boiler & System Operation

BACKGROUND: Boiler system operation is something the operator should be technically capable to operate as this is considered as HPHT (High Pressure High Temperature) equipment. Therefore, the operation team should be those who are competent to handle the job. Boiler & System Operation training is designed to teach the maintenance and safe operation of boiler…

Rp 7.950.000

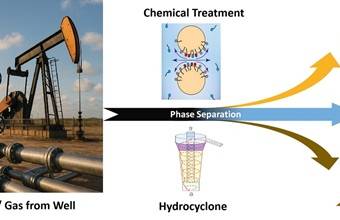

Integrity Chemical Treatment

Background: Dalam industri migas, Integrity Chemical Treatment & Management menjadi fondasi utama dalam menjaga keberlangsungan operasi, efisiensi produksi, dan keselamatan kerja. Salah satu aspek penting dalam pengelolaan integritas aset adalah pemilihan dan penggunaan chemical treatment. Treatment ini tepat untuk mengatasi berbagai tantangan seperti emulsi, wax, scale, korosi, dan pembentukan hydrate. Ketepatan dalam diagnosis dan penanganan…

Rp 7.950.000

Plant Turn Around & Strategic Management

Background Management Outage plays a crucial role in achieving safe, efficient, and cost-effective operational performance. Outage management involves policies, coordination, safety measures, regulatory compliance, technical requirements, and hazardous activities before and after an outage. This training focuses on equipping participants with a comprehensive understanding of the synergistic and continuous processes involved in Planned Outage (PO)…

Rp 8.950.000

Reservoir Simulation

BACKGROUND Production and operation teams cannot directly observe how conditions change within a reservoir during production. Instead, they depend on sophisticated simulation models that transform subsurface. Therefore, reservoir simulation serves as a cornerstone for understanding reservoir performance and optimizing recovery strategies. Integrating geoscience, production data, engineers can forecast future performance under various scenarios, identify operational…

Rp 9.950.000

Pemeliharaan Prediktif Pembangkit

BACKGROUND: Setelah mengikuti pelatihan ini peserta diharapkan faham menganai predictive maintenance pada mesin dan peralatan pembangkit, yang merupakan strategi perawatan dengan pelaksanaan yang didasarkan kondisi mesin/ peralatan itu sendiri atau berdasarkan kondisi (condition based maintenance) dan monitoring kondisi mesin/peralatan (machinery condition monitoring) sebagai penentuan kondisi mesin/peralatan pembangkit dengan cara pemeriksaan secara rutin sehingga dapat diketahui…

Rp 7.950.000