- Selamat datang di website PT Fiqry Jaya Manunggal. Semoga anda senantiasa sehat afiat. Kami siap melayani anda

Integrated Reservoir Management

| Stok | Tersedia |

| Kategori | Oil & Gas |

Integrated Reservoir Management

Background:

Integrated Reservoir Management (IRM) is a structured approach to maximize the value of hydrocarbon assets by combining G&G, Reservoir Engineering, Drilling, Completion, Production, and Economic considerations into a single framework. Through effective integration of data and disciplines, operators can improve recovery factors, extend field life, and optimize development plans. This is where “Integrated” play crucial roles.

In practice, however, many engineers tend to focus narrowly on their own disciplines. For example, Production and Completion Engineers often prioritize well deliverability without paying sufficient attention to reservoir behavior, while geoscientists may overlook operational constraints. These siloed approaches lead to inefficiencies, missed opportunities, and suboptimal recovery. A proper IRM program helps overcome these bad habits by fostering collaboration, aligning objectives, and ensuring every decision accounts for both well performance and reservoir sustainability.

Objectives:

- Understand the principles and importance of integrated reservoir management

- Recognize the risks of siloed decision-making and the value of cross-disciplinary collaboration

- Strengthening Production & Operations involvement in reservoir management

- Apply multidisciplinary approaches to reservoir characterization and development

- Evaluate production performance and identify opportunities for reservoir optimization

- Develop reservoir surveillance programs and integrate monitoring data

- Apply enhanced oil recovery (EOR) and improved oil recovery (IOR) strategies.

- Build effective collaboration between geoscience, engineering, and operations teams.

Recommended Participants:

- Reservoir Engineers

- Geologists and Geophysicists

- Production and Petroleum Engineers

- Drilling and Completion Engineers

- Field Development Planners

- Decision Makers in Reservoir Development

Course Outline:

1. Introduction to Integrated Reservoir Management

- Definition, scope, and objectives of IRM

- Common bad habits: “my wells vs. your reservoir” mindset

- Why integration matters for maximizing recovery

2. Reservoir Characterization

- G&G data integration and Petrophysical evaluation

- Reservoir modeling fundamentals

3. Reservoir Engineering Fundamentals

- Material balance and decline curve analysis

- Fluid flow in porous media

- Drive mechanisms and recovery factors

4. Collaboration with Production & Operations Team in Reservoir Surveillance

- Role of Production and Operations

- Daily well monitoring and field reporting as surveillance inputs

- Building cross-disciplinary awareness between reservoir and Operations

5. Production Data and Performance Evaluation

- Well performance analysis & reservoir pressure data

- Identifying production bottlenecks

- Bridging production/well focus with reservoir sustainability

6. Reservoir Surveillance and Monitoring

- Tools and techniques for surveillance

- Production logging, pressure monitoring, tracer methods

- Integrating real-time data for decision making

7. Reservoir Management Strategies

- Primary, secondary, and tertiary recovery methods

- Waterflooding and gas injection strategies

- IOR/EOR project screening and evaluation

8. Field Development Planning

- Reservoir simulation for forecasting and planning

- Well placement and infill drilling strategies

- Balancing short-term production goals with long-term recovery

9. Risk Management in Reservoir Development

- Identifying and mitigating uncertainties

- Sensitivity analysis and scenario planning

- Cross-disciplinary decision-making

10. Case Studies and Best Practices in IRM

- Lessons learned from siloed vs. integrated approaches

- How poor coordination wastes reservoir potential

- Group discussion and application exercise

About The Course Leader:

FJM’s Asscociate Instructors – Practitioner & Trainer

Integrated Reservoir Management

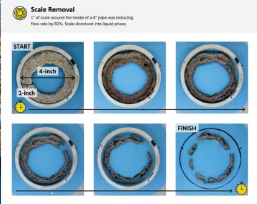

Scale and Corrosion in Oil & Gas Field

BACKGROUND: Scale and Corrosion di lapangan Oil & Gas Field merupakan tantangan utama yang dapat mengurangi efisiensi operasi, meningkatkan biaya pemeliharaan, dan memperpendek umur peralatan. Scale terbentuk akibat pengendapan mineral di dalam sistem, sementara korosi merusak struktur material akibat interaksi dengan lingkungan yang agresif. Masalah ini tidak hanya memengaruhi produktivitas, tetapi juga membawa risiko terhadap…

Rp 7.950.000

Onshore Facilities Infrastructure, Design, Constructions & Operation Optimization

BACKGROUND: Onshore Facilities Infrastructure, Design, Constructions & Operation Optimization are one of the most complex systems among others. It requires team competent in fully integrated approaches starting from initial study, design planning, construction, startup operation and carry on to the post commissioning process. Ideally this includes post start-up review optimization and asset integrity management to…

Rp 7.950.000

6%

Oil & Gas Measurement & Metering Custody

BACKGROUND: This course is developed for engineers and technicians who need to have a practical knowledge of selection, installation and commissioning of oil metering equipment. It is for those primarily involved in achieving effective results in industrial processes. This would involve the design, specification and implementation of control and measurement equipment. The course focuses on…

Rp 7.950.000 Rp 8.500.000

Marginal Fields Development

Background: Marginal fields development refers to discoveries which have not been exploited for long, due to one or more of the following factors: • Very small sizes of reserves/pool to the extent of not being economically viable • Lack of infrastructure in the vicinity and profitable consumers • Prohibitive development costs, fiscal levies and or…

*Harga Hubungi CS

Integrated Production Optimization of Oil & Gas

BACKGROUND: Dalam industri minyak dan gas, tantangan operasional yang kompleks seperti fluktuasi produksi, penurunan cadangan, dan peningkatan biaya operasional membutuhkan pendekatan terpadu untuk mengoptimalkan proses produksi. Pelatihan ini dirancang untuk memberikan pemahaman mendalam tentang konsep dan teknik integrasi dari reservoir, sumur, fasilitas permukaan, hingga jaringan distribusi. Dengan pendekatan ini, peserta dapat mengidentifikasi peluang peningkatan efisiensi,…

Rp 14.950.000

Well Completion and Workover

BACKGROUND: Well Completion and Workover are two activities in oil and gas industry, regardless it is oil or gas wells. Initial completion is the activities to allow production fluid to flow into the well bore and eventually flow to surface facilities. Workover carried out when the oil or gas production start declining overtime. Hence as…

Rp 13.950.000