- Selamat datang di website PT Fiqry Jaya Manunggal. Semoga anda senantiasa sehat afiat. Kami siap melayani anda

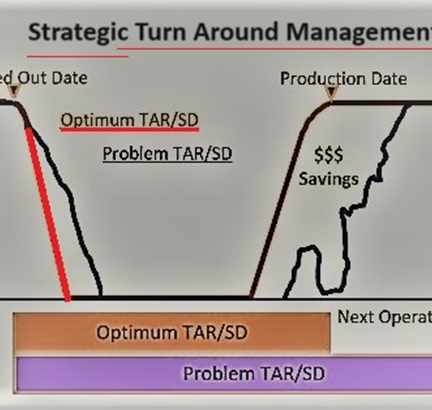

Plant Turn Around & Strategic Management

Rp 8.950.000| Stok | Tersedia |

| Kategori | Maintenance, Mechanical |

Instruktur: Ir. Syafuan Gani, MM

Bandung, 9-12 Juni, 2025

Plant Turn Around & Strategic Management

Background

Management Outage plays a crucial role in achieving safe, efficient, and cost-effective operational performance. Outage management involves policies, coordination, safety measures, regulatory compliance, technical requirements, and hazardous activities before and after an outage.

This training focuses on equipping participants with a comprehensive understanding of the synergistic and continuous processes involved in Planned Outage (PO) maintenance. It covers planning, preparation, execution, control, monitoring, evaluation, and follow-up action plans to ensure seamless and effective maintenance activities.

Objectives

By the end of this training, participants will be able to:

- Understand the scope of Planned Outage (PO) maintenance programs.

- Develop schedules for Overhaul (OH) activities.

- Establish procedures to successfully complete OH tasks.

- Prepare equipment and materials required for OH.

- Monitor, control, evaluate, and report the outcomes of OH implementation.

Recommended Participants

This training is ideal for:

- Operations personnel

- Engineers

- Maintenance teams

- Planners responsible for maintenance planning, cost control, outage management, and asset management.

Course Outline

- Introduction to Outage Management

- Definition and importance of outage management in operational efficiency.

- Scope of Planned Outage (PO) Maintenance Programs

- Determining the scope of work.

- Scheduling of maintenance activities.

- Creating work packages, including resource needs (personnel, materials, tools) and facilities.

- Establishing quality standards and performance targets.

- Budgeting and Cost Management

- Setting budgets and cost allocations for outage activities.

- Communication Methods and Standard Operating Procedures

- Developing standardized procedures for effective communication.

- Overhaul (OH) Execution

- Step-by-step guidance on performing overhaul tasks safely and efficiently.

- Reporting and Documentation of OH Results

- Preparing and submitting detailed reports post-outage.

- Measuring Outage Management Effectiveness

- Key Performance Indicators (KPIs).

- Assessing maturity levels of outage management practices.

Plant Turn Around & Strategic Management

Asset Integrity Management System (AIMS)

BACKGROUND: Asset Integrity Management Systems (AIMS) outline the ability of an asset to perform its required function effectively and efficiently whilst protecting health, safety and the environment and the means of ensuring that the people, systems, processes and resources that deliver integrity are in place, in use and will perform when required over the whole…

Rp 7.950.000

Maintenance Performance Indicator

BACKGROUND: Dalam proses Maintenance, indikator kinerja (KPI) adalah untuk mengukur kinerja tugas yang diberikan. Misal mengukur apa pun mulai dari waktu yang berlalu selama shutdown (terprogram atau tidak) hingga evolusi proses produksi. KPI bervariasi tergantung perusahaannya; tujuan, strategi, dan rencana tindakannya. Namun, ada satu set indikator yang dianggap lebih baik dan lebih sering digunakan. Indikator…

Rp 7.950.000

Rotating Equipment Operation & Maintenance

BACKGROUND: Rotating equipment is commonly used in the industry & plays a vital role in end-to-end production operations. Hence, mastering the principles of rotating equipment is very essential. Identification of failure modes & monitoring methods of failure symptoms are important as well, for establishing the most effective maintenance program. This course begins with discussing the…

Rp 7.950.000

Fundamental Project Management

BACKGROUND: As an individual or as an employee, we often experience challenges in managing unique, non-routine (non-recurring) project activities that involve many parties. The challenges that are often faced are generally how to start and guide the project activities to be completed on schedule with the expected quality and efficient costs. The success of a…

Rp 7.950.000

Analisa & Evaluasi Strategi Pemeliharaan Pembangkit

PENDAHULUAN: Analisa & Evaluasi Pemeliharaan Pembangkit. Tata kelola pemeliharaan unit pembangkitan yang sistematis merupakan hal penting dalam menjalankan seluruh proses bisnis untuk meningkatkan kinerja perusahaan sekaligus meningkatkan daya saing. Tata kelola pemeliharaan pembangkitan yang dilakukan secara efektif dapat menjadikan perusahaan terdepan dalam bidang pembangkitan. Pemahaman proses tata kelola pemeliharaan sistem pembangkit harus dilakukan secara rasional…

Rp 6.950.000

Process Hazard Analysis (PHA)

BACKGROUND: In industrial operations, particularly those involving hazardous processes, the identification, evaluation, and control of potential risks are critical to ensuring safety, environmental compliance, and operational continuity. Process Hazard Analysis (PHA) serves as a systematic approach to identifying hazards, analyzing potential consequences, and implementing measures to mitigate risks. As industrial processes become increasingly complex, the…

Rp 7.950.000