- Selamat datang di website PT Fiqry Jaya Manunggal. Semoga anda senantiasa sehat afiat. Kami siap melayani anda

Oil & Gas Processing Plants

Rp 7.950.000 Rp 8.500.000| Stok | Tersedia |

| Kategori | Engineering, Oil & Gas, Process, Production Operation, Soft Skills |

INSTRUCTOR: Dr. Saripuddin, ST., MT

Bandung, 20-22 Mei, 2025

Oil & Gas Processing Plants

BACKGROUND:

Oil & gas Processing Plants menghadapi tantangan dalam memastikan efisiensi, keselamatan, dan keberlanjutan operasional. Proses pengolahan minyak dan gas melibatkan berbagai tahap mulai dari ekstraksi hingga distribusi, yang memerlukan desain sistem yang optimal dan operasi yang andal.

Pelatihan ini dirancang untuk memberikan wawasan mendalam tentang prinsip desain, proses operasional, dan teknologi yang digunakan di fasilitas pengolahan minyak dan gas. Peserta akan memahami aspek teknis dan manajerial untuk meningkatkan efisiensi operasional dan memitigasi risiko yang berhubungan dengan pengolahan hidrokarbon.

OBJECTIVES:

- Memahami tahapan utama dalam proses pengolahan minyak dan gas, termasuk dehidrasi, desulfurisasi, dan pemisahan hidrokarbon.

- Menganalisis desain fasilitas pengolahan untuk meningkatkan efisiensi operasional.

- Mengidentifikasi tantangan operasional umum dan menerapkan strategi mitigasi risiko.

- Mengaplikasikan standar dan regulasi keselamatan internasional dalam desain dan operasi fasilitas pengolahan minyak dan gas.

- Menggunakan teknologi terbaru untuk mendukung pengolahan hidrokarbon secara optimal dan ramah lingkungan.

- Berkontribusi pada peningkatan performa fasilitas melalui analisis sistem dan evaluasi proses operasional.

RECOMMENDED PARTICIPANTS:

- Process Engineers and Technicians

- Production and Operations Personnel

- Facility Supervisors and Managers

- HSE (Health, Safety, Environment) Officers

- New Graduates or Trainees in Oil & Gas Industry

- Consultants and Project Engineers

COURSE OUTLINE:

Fundamentals Controlling Production

-

- Physical Properties

- Basic Hydrocarbon Chemistry

- Hydrocarbon Fluid Mixtures

- Phase Behavior

Overview of Production Processes

-

- Hydrocarbon reservoirs & reservoir fluid characteristics

- Oil and water handling facilities

- Gas handling facilities

- Process Description

- Operating Problems and Practical Solutions

Separators & Pressure Vessels

-

- Factors affecting separation

- Separator construction

- Gas‐liquid separation (2‐Phase)

- Vessel operation

- Vessel internals

- Separator operation considerations

- Liquid‐liquid separation (3‐Phase)

Emulsions & Oil treating

-

- Emulsion theory

- Factors affecting emulsion stability

- Emulsion treating methods

- Emulsion treating equipment

- FWKO’s

- Vertical/horizontal heater treaters

Water Treatment

-

- Basic considerations

- Process considerations

- API Separators

- Skimmer Tanks and Vessels

- Induced Gas Flotation Units (Mechanical/Hydraulic)

- Hydrocyclones

- Filtration

- Solids removal principles

- Solids removal equipment

Gas Sweetening

-

- Acid gas considerations

- Treating methods

- Process description

- Process selection

Plant Piping & Pipelines

-

- Plant/Offshore facilities

- Gas pipelines and flowlines

- Liquid pipelines

- Pressure ratings

- Determination of spec breaks

Measurement

-

- Inferred vs. direct measurement

- Accuracy

- Types of meters

- Differential pressure

- Positive displacement

- Ultrasonic measurement

- Turbine meters

- ACT Unit Components and Operation

- Basis of meter proving

Process Control & Safety Systems

-

- Elements of a process control system

- Control loops

- Control modes

- PID

- Advanced control

- Production Safety Systems

- Undesirable Events

- Safety Analysis

- SAFE Chart

ABOUT THE COURSE LEADER:

Ir. In Jumanda Kasdadi, M.T

In addition to his duty as lecturer, Mr. Jumanda has delivered almost 280 trainings (public & in-house) in various types of industries, especially for oil and gas companies since 1997. He holds Bachelor and Master Degrees in Chemical Engineering degrees from the Institute Technology Bandung. He has also taken courses for 9 topics in The Oil & Gas fields at PETEX (Petroleum Extension), University of Texas at Austin, in Houston, Texas, USA (2018).

Beyond his formal educations, he has many other professional certificates; Lecturer Certificate from Indonesia Minister of Education; Construction, Electrical and Fire Protection Certificates from HSE Association Indonesia (ALPK3); Risk Based Inspection (RBI) Facilitator, Instrumentation Engineering Design for Oil & Gas Project with INtools (Ref.No OGC01-170516200516-2839); HAZOPS and HAZID Certificates from Indonesia Certifying Agency (BNSP).

Companies where he delivered the training to are mostly major intensive capital such as Pertamina, PHE, PHI, PHR, PHKT, PGN, Chevron, ConocoPhillips, Total Indonesie, CNOOC, Medco, Petrochina, Star Energy, Freeport, Mubadala, Indonesia Power, Geothermal Companies, KAI, US Consulate, Freeport, SKK Migas, Titas (Bangladesh), and petrochemical & mining and others.

Ir. In Jumanda K, MT was directly involved in many projects of Feasibility Studies (FS), and further Front-End Engineering Design (FEED), Detail Engineering Design for Construction (DEDC) in oil/gas industry, Risk-Based Inspection (RBI), HAZID, HAZOPS, QRA, FTA, SIL Classification, etc; for national and international companies.

Oil & Gas Processing Plants

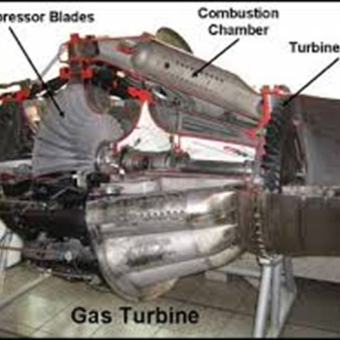

Gas Turbine & Compressor Operation & Maintenance

BACKGROUND: Gas turbines and compressors are critical components in various industries, including power generation, oil and gas, and petrochemicals. Their efficient operation and maintenance are essential for ensuring reliability, optimizing performance, and minimizing downtime. This training program is designed to provide participants with a comprehensive understanding of gas turbine and compressor systems, including their principles…

Rp 7.950.000

Safety Instrumented System (SIS) and Control

BACKGROUND: Process safety is a critical element in industries involving high-risk operations, such as oil and gas, petrochemicals, and manufacturing. One of the main components in process safety management is the Safety Instrumented System (SIS). SIS is designed to protect personnel, the environment, and assets from potential incidents that can cause significant losses. This training…

Rp 7.950.000

Remaining Life Assessment

BACKGROUND: Remaining life assessment (RLA) is an attempt to measure, predict the remaining life of an equipment, ie. a boiler or other critical equipment in a plant. By knowing the remaining life of an equipment or part thereof, technicians can plan replacement or repair. It is also very important aspect from safety, operation, and asset…

Rp 7.950.000

Power Plant Performance Test

BACKGROUND: The main reasons to conduct a power plant performance test are: Identify the baseline performance of the power plant in different operating cases Quantify the prior/after performance improvement due to a major maintenance outage. Verify if the power plant meets the specifications of the applicable purchase contract, therefore if liquidated damages or “make good”…

Rp 7.950.000

Wells Performance & Surveillance

BACKGROUND: Effective monitoring and surveillance of well performance are critical to optimizing production, identifying operational inefficiencies, and maintaining the integrity of wells over time. Wells Performance & Surveillance is a comprehensive approach that involves the collection, analysis, and interpretation of data from wells to improve performance and decision-making. This training provides participants with the knowledge…

Rp 13.950.000

Enhance Oil Recovery (EOR)

INTRODUCTION: EOR (Enhance Oil Recovery)adalah metode perolehan minyak tahap lanjut dengan cara menambahkan energi berupa dari material atau fluida pendorong khusus yang tidak terdapat dalam reservoir minyak secara alami. EOR kabanyakan diterapkan pada lapangan atau sumur minyak tua yang telah kehilangan atau kehabisan tenaga dorong produksi dari sumur atau lapangan itu sendiri. Umumnya, EOR diterapkan…

Rp 14.950.000