- Selamat datang di website PT Fiqry Jaya Manunggal. Semoga anda senantiasa sehat afiat. Kami siap melayani anda

Advanced Centrifugal Compressor

| Stok | Tersedia |

| Kategori | Maintenance, Mechanical, Oil & Gas, Power Generation, Soft Skills |

30 June - 4 July, 2025 - Bandung

Instructor: William C Cawthon

Advanced Centrifugal Compressor

BACKGROUND:

This training course will be presented as PowerPoint Presentations, discussions drawn from many years of operation and maintenance experience working around the world. Questions and examples based on past experiences will be used throughout this presentation and participants are encouraged to ask questions and discuss examples from their own experiences.

OBJECTIVES:

This Centrifugal Compressor Course will highlight:

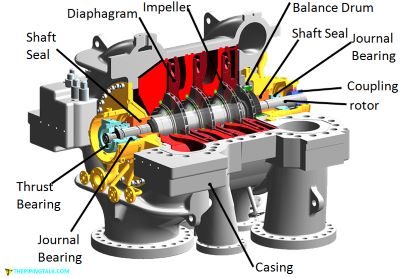

- Centrifugal Compressor Components and Their Function

- Centrifugal Compressor Maintenance – Disassembly, Inspection and Reassembly

- Standard Repair Processes for Compressor Components

- Centrifugal Compressor Operation, Control and Troubleshooting

By the end of this Centrifugal Compressor training course, participants will be able to:

- Describe various Compressor Designs and Features and Applications of Each.

- Describe and Understand Each Compressor Component

- Gain Knowledge in Compressor Component Construction.

- Gain Knowledge in the normal maintenance performed on centrifugal compressors.

- Learn About in Repair and Refurbishment of Centrifugal Compressors

- Gain Knowledge in the Operation and Control of Centrifugal Compressors.

- Gain Knowledge in Troubleshooting Compressor Problems

RECOMMENDED PARTICIPANTS:

- Control Room and Field Operators

- Maintenace Engineers and Mechanics

- Maintenance Supervisors

- Plant Personnel requiring a working level knowledge of Centrifugal Compressors

- Plant Personnel dealing with equipment condition monitoring and reliability.

COURSE OUTLINE:

Introduction to Centrifugal Compressor Training

The journey begins with a comprehensive overview of centrifugal compressors. This first session covers the fundamentals, including compression methods and an introduction to compressor types. Participants will explore positive displacement and dynamic compressors while learning how to select the right compressor for specific applications. Additionally, detailed descriptions of centrifugal compressor types provide clarity on their unique characteristics and uses.

Understanding the Design and Components of Centrifugal Compressors

As the training progresses, the focus shifts to the intricate design and construction of centrifugal compressors. This session dives into the various components and their functions, offering a thorough understanding of the machine’s anatomy. Topics include the compressor casing, aero assembly, diaphragms/diffusers, and rotors. Participants will also learn about critical parts like impellers, balance drums, thrust collars, coupling hubs, radial and thrust bearings, and seals, including oil seals, dry gas seals, and barrier seals. To complete the module, the lube oil, seal oil, and seal gas systems will be discussed in detail, emphasizing their roles in compressor operation.

Ensuring Reliability Through Maintenance

The third segment focuses on centrifugal compressor maintenance to ensure reliability and efficiency. Participants will review recommended maintenance schedules and strategies, including run-to-failure, preventive, predictive, and reliability-centered maintenance. Hands-on insights into standard disassembly, inspection, and reassembly processes provide practical knowledge for maintaining these machines. The module also outlines the repair process for compressors and their components, empowering participants to handle common maintenance tasks confidently.

Mastering Compressor Control and Operation

Understanding how to control and operate centrifugal compressors is critical for achieving peak performance. This segment introduces participants to essential support systems, including the lube oil, seal oil, and seal gas systems. Monitoring systems for vibration, temperature, and performance are also highlighted. The training includes step-by-step guidance on compressor operation cycles, covering valve positions for prestart, normal startup, reset, and shutdown sequences. Special attention is given to anti-surge/recycle valve operations during both startup and shutdown processes. Emergency shutdown procedures, whether pressurized or depressurized, are also addressed. Finally, participants will gain insights into performance curves, the compressor map, flow rate limits, surge, stonewall, and operating speed limits.

Troubleshooting Centrifugal Compressors: A Practical Approach

The final module focuses on diagnosing and resolving issues in centrifugal compressors. Through case studies and real-world scenarios, participants will refine their troubleshooting skills. This interactive session provides ample opportunities for questions and answers, ensuring that participants leave the course with a clear understanding of the concepts covered and practical strategies for addressing challenges in the field.

ABOUT THE COURSE LEADER:

William C Cawthon

Mr. Cawthon is a practitioner (Bill), self-motivated and focused person who has over six years of experiences working in senior managerial roles, and over 35 years’ technical experience, managing people and projects. His last position in Indonesia was Vice President & Operation Director of Sulzer Turbo Services Indonesia for almost 5 years managing more than 150 people. He also spent his time as Singapore Country Head of Sulzer Rotating Equipment Services for 3 years. He was also member of Asia Pacific Management Team, Reporting to the Asia Pacific President.

In the fields, he has very broad industrial experiences in oil & gas, petrochemical, power generation, geothermal, and also pulp & papers. Mr. Bill has the opportunities to worked in various countries such as: Indonesia for sure, Singapore, China, Rusia, Taiwan and surely abundant of good track records & accomplishments in USA, his home country.

Mr. Bill started his career as Electrician Mate in US Navy for more than 5 years, continued as Field Service Engineer also for more than 5 years. He was responsible for installation, start up, repair, commissioning, operation & troubleshooting of centrifugal compressors, integral gear compressors, gears, steam turbines and pumps with all related Auxiliaries Systems.

When he was then assigned as Field Engineer in USA (1990-2006). In addition to his routine jobs, he also conducted training for onsite personnel on the operation, repair & maintenance of all equipment and helped onsite personnel to set up maintenance & parts inventory.

Since 2016 Mr. Cawthon spends his time as Consultant in Rotating Equipment after having more than 30 years of solid experience in this area, starting as a technician all the way up to Top Level Management positions in Asia Pacific Region.

Advanced Centrifugal Compressor

Precision Machinery Shaft Coupling Alignment

BACKGROUND: Precision alignment is the process of accurately positioning the shafts of rotating equipment, such as pumps, compressors, and turbines, to ensure they are aligned within specified tolerances. This minimizes vibration, reduces wear on components, and enhances the performance, reliability, and lifespan of the machinery. In rotating equipment, vibrations often result in severe problems and…

Rp 9.500.000

Fundamental Project Management

BACKGROUND: As an individual or as an employee, we often experience challenges in managing unique, non-routine (non-recurring) project activities that involve many parties. The challenges that are often faced are generally how to start and guide the project activities to be completed on schedule with the expected quality and efficient costs. The success of a…

Rp 7.950.000

Lifting Operation Oil & Gas

BACKGROUND: Lifting operation adalah usaha yang dilakukan oleh production engineer dan tim production engineer untuk mengangkat minyak dan gas dari dasar sumur ke permukaan, baik melalui sumur sumur alam (natural flow) mau pun sumur – sumur buatan (artificial lift). Biasanya artificial lift yang sering digunakan adalah Gas Lift well, Sucker Rod Pump well, Electric Submersible…

Rp 14.950.000

Gas & Diesel Engines Operation & Maintenance

BACKGROUND: Most facilities require some type of prime mover to supply mechanical power for pumping, electrical power generation, operation of heavy equipment, and to act as a backup electrical generator for emergency use during the loss of the normal power source. Although several types of prime movers are available (gasoline engines, steam and gas turbines),…

Rp 7.950.000

Project Management & Scheduling using Primavera

BACKGROUND: Manajemen proyek dan penjadwalan yang efektif adalah kunci keberhasilan dalam menyelesaikan proyek tepat waktu, sesuai anggaran, dan dengan hasil yang memuaskan. Proyek yang kompleks memerlukan pendekatan yang sistematis untuk merencanakan, mengatur sumber daya, serta memantau kemajuan secara real-time. Primavera merupakan perangkat lunak yang dirancang untuk membantu para profesional mengelola semua aspek proyek secara efisien…

Rp 6.950.000

Bearing & Lubrication Technology

BACKGROUND: Bearings are machine components support and position the rotor of the machine to ensure they are in the correct position. Supported by proper lubrication and the availability of power then; The rotor rotates with the correct alignment; The machine is free from excessive vibration; The rotor and stator are free from excessive friction so…

Rp 7.950.000