- Selamat datang di website PT Fiqry Jaya Manunggal. Semoga anda senantiasa sehat afiat. Kami siap melayani anda

Oil Water Treatment Technology

Rp 7.950.000| Stok | Tersedia |

| Kategori | Maintenance, Production Operation, Training |

Trainer: Ir. In Jumanda Kasdadi MT.

Bandung, 7-9 Octoober 2025

Oil Water Treatment Technology

BACKGROUND:

Oil-water treatment technology plays a crucial role not only in the petroleum industry but in most of major intensive capital corporation WHO CARE about environment, where efficient separation of oil and water is essential for environmental compliance and operational efficiency. This course delves into the principles, processes, and advanced techniques for treating oil-contaminated water, addressing theoretical foundations and practical applications.

Through comprehensive learning modules and case studies, this course equips professionals with the knowledge to implement effective oil-water treatment strategies, ensuring sustainable practices and regulatory adherence within the industry.

OBJECTIVES:

- Understand the fundamental principles of oil-water separation technology.

- Learn various methods and technologies used in oil-water treatment.

- Gain practical knowledge in implementing chemical and mechanical separation processes.

- Explore advanced techniques such as electrocoagulation and membrane filtration.

- Achieve proficiency in optimizing treatment efficiency and environmental compliance.

- Develop skills in troubleshooting and maintaining oil water treatment systems.

- Acquire knowledge of regulatory requirements and best practices in the industry.

- Analyze case studies to apply theoretical knowledge to real-world scenarios.

TRAINING CONTENTS:

- Water chemistry fundamentals

- Water sampling and analysis

- Water formed scales

- Corrosion control

- Water treatment microbiology

- Produced water discharge/disposal and treatment principles

- Produced water treating equipment – theory of operation, advantages and disadvantages, and the importance of oil droplet size

- Water injection and disposal systems – theory of operation, corrosion, scale, and biological control

- Case studies

WHO SHOULD PARTICIPATE?

- Environmental Engineers and Specialists.

- Oil and Gas Industry Professionals.

- Water Treatment Plant Operators.

- Regulatory Compliance Managers.

- Chemical Engineers.

- Environmental Consultants.

TRAINER:

Ir. In Jumanda Kasdadi MT.

Mr. Jumanda, a dedicated lecturer, has conducted nearly 280 training sessions (both public and in-house) for various industries, with a strong focus on oil and gas companies since 1997. He holds both Bachelor’s and Master’s degrees in Chemical Engineering from the Institute Technology Bandung. In addition, he has completed nine specialized courses in the oil and gas sector at PETEX (Petroleum Extension), University of Texas at Austin, in Houston, Texas, USA, in 2018.

Apart from his formal education, Mr. Jumanda possesses numerous professional certifications. These include a Lecturer Certificate from the Indonesian Minister of Education, Construction, Electrical, and Fire Protection Certificates from the HSE Association Indonesia.

Anda mungkin membutuhkan:

Oil Water Treatment Technology

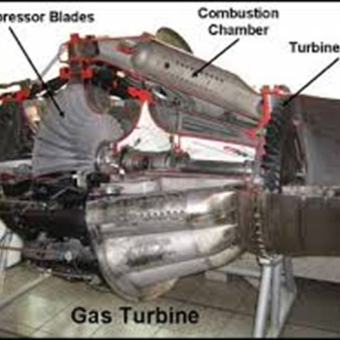

Gas Turbine & Compressor Operation & Maintenance

BACKGROUND: Gas turbines and compressors are critical components in various industries, including power generation, oil and gas, and petrochemicals. Their efficient operation and maintenance are essential for ensuring reliability, optimizing performance, and minimizing downtime. This training program is designed to provide participants with a comprehensive understanding of gas turbine and compressor systems, including their principles…

Rp 7.950.000

Process Hazard Analysis (PHA)

BACKGROUND: In industrial operations, particularly those involving hazardous processes, the identification, evaluation, and control of potential risks are critical to ensuring safety, environmental compliance, and operational continuity. Process Hazard Analysis (PHA) serves as a systematic approach to identifying hazards, analyzing potential consequences, and implementing measures to mitigate risks. As industrial processes become increasingly complex, the…

Rp 7.950.000

ROTATING MACHINERIES

BACKGROUND: Rotating machineries, or turbomachinery, involves a component that transfers energy between a fluid and the machine. This transfer can occur from the rotor to the fluid, making it a pump or a fan, or from the fluid to the rotor, making it a turbine. Examples of such machinery include fans, pumps, compressors, turbines, and…

Rp 7.950.000

Flow & Level Custody Measurement

BACKGROUND: This course is designed to acquaint users with the problems and solutions for high accuracy transfer of liquid and gas petroleum products from supplier to customer. These needs have been brought about by major changes in manufacturing processes and because of several dramatic circumstantial changes such as: the increase in the cost of fuel…

Rp 7.950.000

Well Completion and Workover

BACKGROUND: Well Completion and Workover are two activities in oil and gas industry, regardless it is oil or gas wells. Initial completion is the activities to allow production fluid to flow into the well bore and eventually flow to surface facilities. Workover carried out when the oil or gas production start declining overtime. Hence as…

Rp 13.950.000

Surface Wellhead System

Background The surface wellhead system plays critical role ensuring safe & efficient control of hydrocarbons from the reservoir to processing facilities. Positioned on surface, wellhead serves as the primary interface between subsurface operations & topside facilities. It provides structural and pressure control throughout the well’s life cycle. Among its key components, the Christmas tree enables…

Rp 6.350.000