- Selamat datang di website PT Fiqry Jaya Manunggal. Semoga anda senantiasa sehat afiat. Kami siap melayani anda

Boiler & System Operation

Rp 7.950.000| Stok | Tersedia |

| Kategori | Maintenance, Power Generation, Production Operation |

Trainer: Drs. Maridjo, ST., MT

Bandung, 2-4 September, 2025

Boiler & System Operation

BACKGROUND:

Boiler system operation is something the operator should be technically capable to operate as this is considered as HPHT (High Pressure High Temperature) equipment. Therefore, the operation team should be those who are competent to handle the job.

Boiler & System Operation training is designed to teach the maintenance and safe operation of boiler and steam systems. Participants will study pressurized vessels, boiler operation safety skills, troubleshooting techniques, and preventative maintenance guidelines. Application of these skills as well as experience on actual equipment should provide the participant with knowledge and skills to diagnose and repair equipment malfunctions.

OBJECTIVES:

After attending this training, the participant will learn the materials below:

- The installation, operation, maintenance and management of boiler plants

- The steam and combustion processes

- Safe boiler operation techniques

- About pollutants and the technologies that exist to reduce emission levels

- How to achieve peak boiler plant efficiencies

- How to identify and troubleshoot boiler problems quickly and Efficiently.

TARGETED PARTICIPANTS:

- Senior Boiler Plant Operators, Repairers & Installers

- Boiler Plant Engineers

- Operation, Maintenance, Inspection & Repair Managers, Supervisors & Engineers

- Mechanical Engineers & Technicians

- Design Engineers, Insurance Company Inspectors

TRAINING CONTENT:

-

INTRODUCTION:

-

- Types of package boilers and their applications

- Boiler components, terminology and definitions

-

FUEL COMBUSTION AND STEAM GENERATION PROCESS:

-

- Overview of the boiler heating and steam generation process

- Influence of fuel types on boiler design and operation

- Firing appliances

- Basics to the theory of combustion and fundamentals of steam generation

- Thermal efficiency

- Fire-side deposits and their influences

-

BOILER AUXILIARY PLANT:

-

- Water treatment and dosing plant

- Feed water pumps, valves, steam traps, piping, fans, and dampers

- Firing systems

- Economizers and heat recovery equipment

- Flue gas cleaning and dust removal

- Soot blowers

-

OPERATIONS AND CONTROLS:

-

- Boiler instrumentation and its purpose

- Typical P&I diagrams for coal/oil fired package units

- OEM operating manuals

- Control systems or loops

- Operation and control philosophy, sequences and procedures

- Safety equipment and emergency procedures

- Typical operational problems, reasons for the problems

- Troubleshooting

- Operating records and logs

- The do’s and don’ts of boiler operation and corrective action

-

PRESSURE CONTAINING COMPONENTS:

-

- Basics to codes calculation theory and assumptions

- Overview of design parameters for shell, furnace, plates and tubing Importance of pressure part inspection.

-

PLANNING AND MANAGING BOILER MAINTENANCE:

-

- Critical importance of maintenance policies and programs

- Manufacturers literature and requirements

- Regularity of inspections and maintenance

- Critical items for maintenance for safety, efficiency and reliability

- Country/state legislation regarding inspection and repairs

- Authorized inspection authority involvement

- Maintenance records and preventative maintenance

- In-house vs contractor repair maintenance

- The do’s and don’ts in terms of boiler maintenance

-

MANAGING BOILER REPAIRS, TROUBLESHOOTING & MODIFICATIONS:

-

- When does a boiler repair become a boiler modification?

- Importance of historical records

- Understanding the steps and requirements when undertaking modifications

- Boiler owner and contractor responsibilities

- AIA and their inspection points

- The do’s and don’ts regarding boiler repairs

-

COLD STORAGE OF A BOILER:

-

- Importance of an established storage period, preservation steps and return of the boiler

- Storage instructions and procedures

- Consequences of no plan

-

EMISSION CONTROLS AND ENVIRONMENTAL CONSTRAINTS:

-

- Types of emissions for different fuels fired

- Control of boiler flue gas emission

- Flue gas cleaning and scrubbing equipment

- Oil and gas burner design to reduce NOx emissions

- Effectiveness of gas cleaning or scrubbing equipment

- Acceptable emission levels

TRAINER:

Drs. Maridjo, ST., MT

Maridjo, Drs, S.T., M. T., adalah alumni dari Teknik Mesin Institut Teknologi Bandung (ITB). Dia telah menjadi dosen di PEDC dan sekarang sebagai dosen di teknik mesin Polytechnique ITB (POLBAN). Telah mengajarkan banyak topik terkait keahliannya ke banyak perusahaan di Indonesia, seperti pemeliharaan prediktif dan preventif, sistem pelumasan, mesin diesel, pompa, turbin gas, perpipaan dan perpipaan, kompresor, boiler, dan banyak lainnya. Banyak peserta dari perusahaan telah dilatih dan berkolaborasi dengannya seperti Chevron, Semen Gresik, semen Baturaja, Pertamina, Pusri, GGPC, karyawan Qatar dan perusahaan minyak dan gas Libya, UP IV Balongan pertamina, PT. Indocement, beberapa PLTA, beberapa hotel, PT.Pupuk Kujang, PT.Bio Farma, BPPT, PT. Bintang Agung, beberapa perusahaan minyak dan gas lain di Indonesia dan lain-lain.

Boiler & System Operation

Boiler Control & Burner Management System

OBJECTIVES: Participant will be able to: Understand the benefit of improved boiler process control and saving as result of improved efficiency Develop proper control system documentation Apply principles and methods for flow level measurements to improved boiler operations Specify appropriate strategies for flow, level and pressure control Tuning of boiler control system Implement analyzer measurements…

Rp 6.950.000

Gas & Diesel Engines Operation & Maintenance

BACKGROUND: Most facilities require some type of prime mover to supply mechanical power for pumping, electrical power generation, operation of heavy equipment, and to act as a backup electrical generator for emergency use during the loss of the normal power source. Although several types of prime movers are available (gasoline engines, steam and gas turbines),…

Rp 7.950.000

Oil & Gas Surface Facilities and Measuring System

PENDAHULUAN: Industri minyak dan gas mencakup aktifitas yang sangat luas, sejak tahap eksplorasi sampai dengan eksploitasi serta melibatkan disiplin ilmu yang sangat kompleks. Yang kasat mata adalah kegiatan di atas permukaan (oil & gas surface facilities and measuring system). Karena sifat minyak/gas yang mudah terbakar, maka diperlukan tenaga berkompeten untuk menanganinya. Satu disiplin ilmu saja…

Rp 14.950.000

Alignment and Balancing Theory & Practice

Alignment and Balancing Theory & Practice Using Android INTRODUCTION: Dalam rotating equipment, masalah vibrasi sering terjadi dan sering berakibat menghambat proses produksi. Karena vibrasi yang berlebihan dapat menimbulkan kerusakan baik alat itu sendiri maupun peralatan lain yang berhubungan. Salah satu penyebab vibrasi yang sering kali terjadi adalah masalah pada alignment dan unbalance. Pada pelatihan ini…

Rp 7.950.000

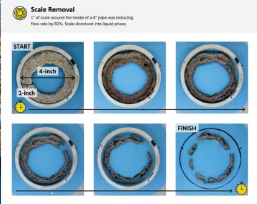

Scale and Corrosion in Oil & Gas Field

BACKGROUND: Scale and Corrosion di lapangan Oil & Gas Field merupakan tantangan utama yang dapat mengurangi efisiensi operasi, meningkatkan biaya pemeliharaan, dan memperpendek umur peralatan. Scale terbentuk akibat pengendapan mineral di dalam sistem, sementara korosi merusak struktur material akibat interaksi dengan lingkungan yang agresif. Masalah ini tidak hanya memengaruhi produktivitas, tetapi juga membawa risiko terhadap…

Rp 7.950.000

Failure Mode and Effect Analysis (FMEA)

BACKGROUND: Failure mode and effect analysis adalah alat yang sangat bermanfaat untuk mencegah kegagalan proses dan produk. FMEA adalah metoda untuk mengidentifikasi dan mengevaluasi kegagalan potensial, menentukan tingkat resiko dari dari kegagalan dan skala prioritas untuk mengambil tindakan yang diperlukan. FMEA dapat menekan biaya karena kegagalan produk. Lebih dari itu, FMEA dapat berfungsi sebagai database…

Rp 7.950.000