- Selamat datang di website PT Fiqry Jaya Manunggal. Semoga anda senantiasa sehat afiat. Kami siap melayani anda

Power Plant Performance Test

Rp 7.950.000| Stok | Tersedia |

| Kategori | Maintenance, Manajemen, Power Generation, Production Operation, Training |

1 - 3 July, 2025 - Bandung

Intructor: Dr. Willy Adriansyah, ST, MM

Power Plant Performance Test

BACKGROUND:

The main reasons to conduct a power plant performance test are:

- Identify the baseline performance of the power plant in different operating cases

- Quantify the prior/after performance improvement due to a major maintenance outage.

- Verify if the power plant meets the specifications of the applicable purchase contract, therefore if liquidated damages or “make good” actions are required.

A performance test is usually carried out after the construction or retrofit of a plant. It verifies that the plant can achieve its guaranteed parameters and function as intended. This 3-day training is designed to provide participants with the knowledge of power plant testing evaluation & efficiency improvements.

OBJECTIVES:

- Demonstrate working knowledge of terminology associated with Plant efficiency

- Describe the terms of Thermodynamic

- Define the terms of entropy, enthalpy, latent heat, sensible heat rate, etc.

- Thermodynamic process involves in each component of power plant

- Describe how changes in heat rate affect operating cost

- Describe the basic principle of boiler, steam turbine & heat exchanger

- Describe how boiler, turbine and heat exchanger affect heat rate

- Common areas of efficiency loss in power plant

- Describe the principle of plant efficiency testing using ASME Performance Test Code

- Data evaluation & plan for improvements

RECOMMENDED PARTICIPANTS:

- Power Plant Operators

- Process & Engineering Staffs

- Management & Business Staffs involved in Power Plant Aspects

COURSE OUTLINE:

- ASME Performance Test Code

- Thermodynamic

- Steam Generators: theory, heat transfer, fuel consideration, auxiliary equipment, etc

- Steam Generator Combustion Theory & Equipment: theory & equations, fuel analysis, combustion equipment, efficiency testing & monitoring

- Steam Turbine: theory, type, construction detail, valves, efficiency

- Factors influencing Turbine Efficiency: steam condition, exhaust loss, size, configuration, mode of operation, mechanical condition, etc.

- ASME Performance Test Code for Turbine: practical aspects of turbine testing, thermal kits, generator corrections, calculation of change in heat rate, calculation of primary flow, diagnosis of turbine problems, example of simplified test calculation, example of testing program

- Power Plant Heat Exchanger: heat transfer theory, condenser testing

- Factors Affecting Heat Exchanger Performance: low circulating water flow rate, high air leakage, fouled tubes, high inlet water temperature, reduction in load, etc

- Centrifugal Pump: theory, design & construction, testing & monitoring operation

- Measuring Equipment: temperature, pressure, flow, electrical, flue gas, data logging & computer

- Evaluation: statistics, test design, data analysist & trending

ABOUT THE COURSE LEADER:

Dr. Willy Adriansyah, ST, MM graduated from Bandung Institute of Technology specializing on energy conservation. Post graduate program also obtained from ITB while the Doctoral is from Norway.

In addition to his duty as a lecturer, he has got abundant of real industrial experiences especially in power generation & oil/gas companies. Since 2013 he has completed many power generation performance tests; Cilegon, Lumut Balai, Ulu Belu, Dieng, Patuha and also other piping & coal handling optimization related to power generation.

Clients uses his services such as: PT. Indonesia Power, PT. Star Energi, PT. PLN, Total Indonesie, PT. Pama Persada, Chevron & Pertamina.

Power Plant Performance Test

Risk Based Inspection (RBI)

BACKGROUND: Risk-based inspection (RBI) is the process of developing an inspection plan based on knowledge of the risk of failure of equipment. This is the combination of an assessment of the likelihood (probability) of failure due to flaws, damage, deterioration, or degradation with an assessment of the consequences of such failure. With RBI, you can…

Rp 7.950.000

Taxation, Legal and Financial Aspects of PSC

BACKGROUND: Taxation, Legal, and Financial Aspects of Production Sharing Contracts (PSC) focuses on equipping participants with a comprehensive understanding of the complex tax regulations and legal frameworks governing PSCs in Indonesia. As one of the primary models for oil and gas exploration and production, PSCs involve intricate financial structures, cost recovery mechanisms, and tax obligations…

Rp 14.500.000

Life Cycle Cost Management

BACKGROUND: Life Cycle Cost Management (LCC) adalah metode sistematis untuk mengelola total biaya aset sepanjang siklus hidupnya, mulai dari perencanaan, pengoperasian, hingga penghentian. LCC membantu perusahaan mengidentifikasi dan mengoptimalkan biaya, meningkatkan keandalan aset, serta mendukung pengambilan keputusan strategis yang efisien. OBJECTIVES: Untuk meningkatkan kesadaran biaya. Penerapan LCC akan meningkatkan kesadaran manajemen dan Teknikal tentang faktor-faktor…

Rp 7.950.000

Boiler Control & Burner Management System

OBJECTIVES: Participant will be able to: Understand the benefit of improved boiler process control and saving as result of improved efficiency Develop proper control system documentation Apply principles and methods for flow level measurements to improved boiler operations Specify appropriate strategies for flow, level and pressure control Tuning of boiler control system Implement analyzer measurements…

Rp 6.950.000

Rotating Equipment & Machineries

BACKGROUND: Rotating equipment & machineries, or turbomachinery, involves a component that transfers energy between working fluids and the machine. This transfer can occur from the rotor to the fluid, making it a pump or a fan, or from the fluid to the rotor, making it a turbine. Examples of such machinery include fans, pumps, compressors,…

*Harga Hubungi CS

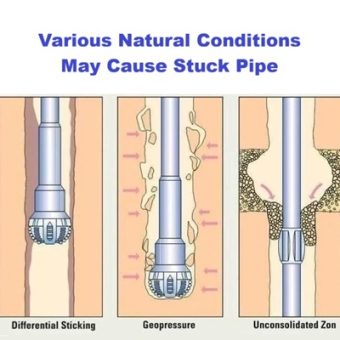

Stuck Pipe Prevention

Background: Stuck pipe is one of the most critical and costly problems in drilling operations across the Oil & Gas and Geothermal industries. With more complex well trajectories, smaller hole sizes, and an industry push to “drill to the limit,” the risk of stuck pipe incidents has grown significantly. Although rigs are now supported by…

*Harga Hubungi CS